Background

A certain company complained of low voltage that is allegedly causing breakdowns/burnouts of their chiller control boards (VSOP Board – Variable Speed Oil Pump). Further, frequent occurrences of power disturbances are affecting their operation.

As a stopgap remedy, the company is forced to operate their generator sets during the afternoon (around 3PM to 6PM) to avert possible downtime due to power disturbances. However, the company is concerned of the financial impact of the generator operation, operation downtimes, and frequent replacement of their chillers’ VSOP board (each board costs approximately Php 100,000).Situation Analysis

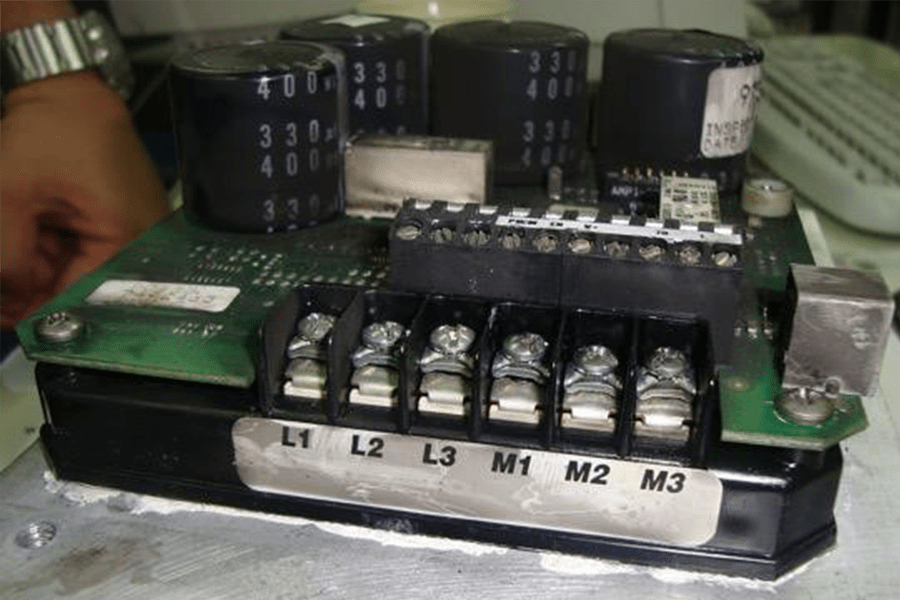

During a site visit and inspection, the company’s engineer in charge was kind enough to give details of the VSOP board and even showed a broken unit. Figures 1 and 2 are pictures of the VSOP board.

The VSOP board is a motor drive that is air-cooled, transistorized, PWM (Pulse Width Modulation) inverter in a very compact package. The chillers use it as a replacement of the old mechanical valve system used in the past to regulate oil pressure..

According to the company’s engineer, they often experience a VSOP failure/burnout after a power disturbance. He added that they have already replaced several VSOP boards in the past.

Figure 1. VSOP Board

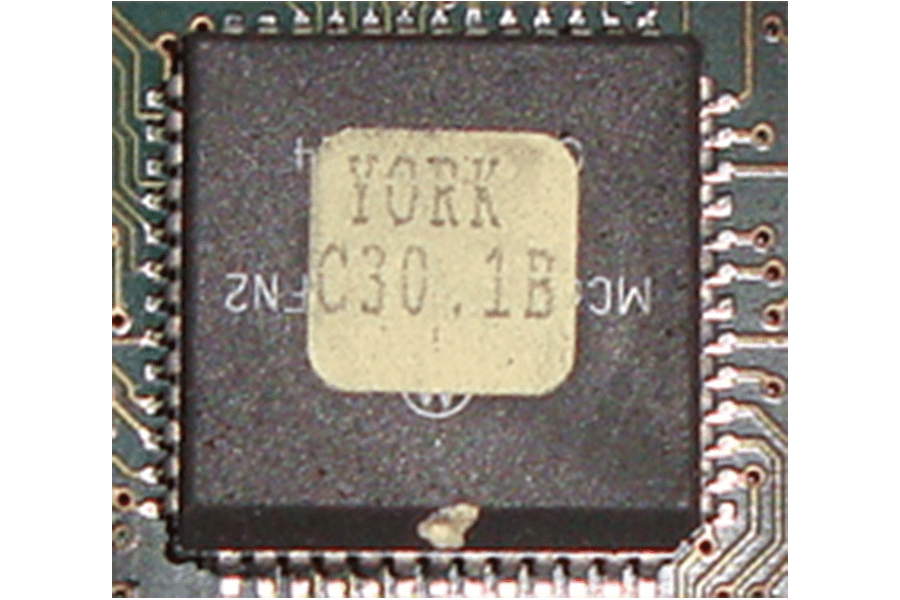

Figure 2. VSOP Board of the chip label software version.

Figure 3. VSOP Board. Zoomed view

The VSOP board is a motor drive that is air-cooled, transistorized, PWM (Pulse Width Modulation) inverter in a very compact package. The chillers use it as a replacement of the old mechanical valve system used in the past to regulate oil pressure.

According to the company’s engineer, they often experience a VSOP failure/burnout after a power disturbance. He added that they have already replaced several VSOP boards in the past.Solution

After investigation, it was found out that the early version of the VSOP drive software is faulty. Voltage disturbances cause the DC bus voltage of the VSOP to exceed a safe limit for an extremely short period of time that results in the premature failure of the VSOP control board.

To prevent premature failure of the VSOP boards, it was recommended to only acquire VSOP boards with drive software that is at least version C30.2A.

The company was very please with the findings and recommendation. No subsequent failures were reported since then.